Centrifuges are widely used in biology, chemistry, medicine and other fields. It separates the different components of the sample through the action of centrifugal force, so as to realize the analysis and research of the sample. The development of centrifuges dates back to the 17th century, and today, centrifuges have become an indispensable tool in scientific research and laboratories.

Principle and classification of centrifuges

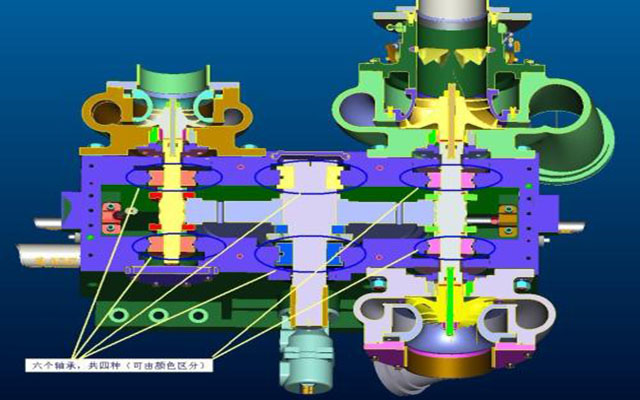

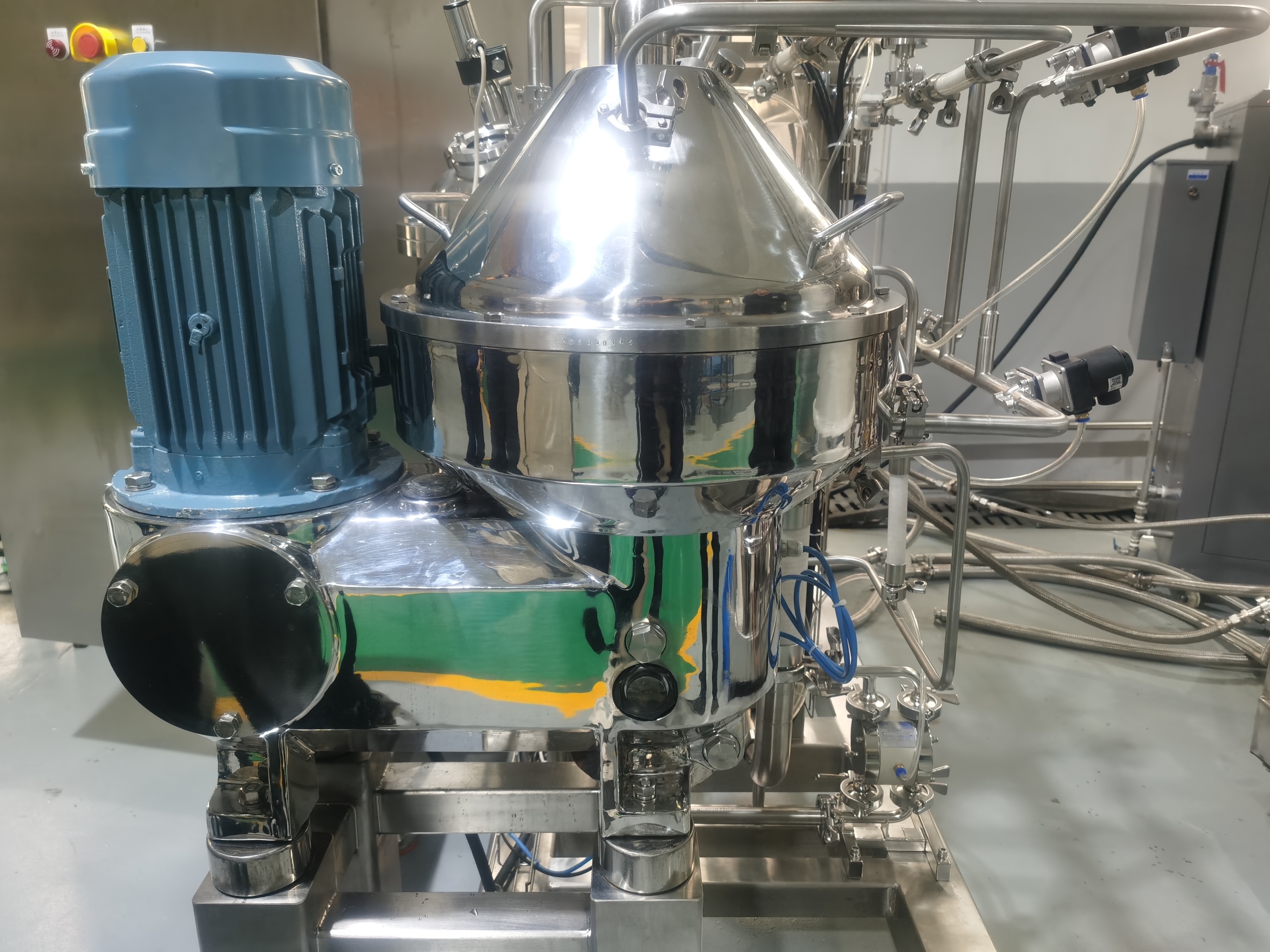

The basic principle of centrifuge is to use the effect of centrifugal force to separate the different components of the sample. Centrifugal force is generated by the rotating centrifuge rotor, when the sample is loaded into the centrifuge rotor, the rotor begins to rotate, and the groups in the sample are affected by the centrifugal force, thus separating. Centrifuges can be divided into many types according to the way centrifugal force is generated and the form of centrifuge rotor.

- Table centrifuge: Table centrifuge is the most common type of centrifuge, suitable for small-scale laboratory work. It usually has a small capacity, low speed, but the operation is simple and convenient, suitable for conventional centrifugal separation experiments.

- High-speed centrifuges: High-speed centrifuges are used for experiments requiring higher centrifugal force, such as cell separation, DNA extraction, etc. It has a larger capacity and higher rotational speed, and is able to generate greater centrifugal force, resulting in more efficient separation.

- Ultra-centrifuge: Ultra-centrifuge is one of the most advanced centrifuges, capable of producing extremely high centrifugal force. It is mainly used to separate protein, nucleic acid and other polymer compounds, with a high degree of separation effect and accurate control ability.

Second, the application of centrifuges in biological research

Centrifuges play a vital role in biological research. It can be used to separate biological samples such as cells, organelles and proteins, so as to realize the study of their structure and function. Here are a few typical applications of centrifuges in biological research. - Cell separation: Centrifuges can be used to separate different types of cells. By adjusting the centrifuge speed and centrifuge time, different types of cells can be settled to different locations, thus achieving separation.

- DNA extraction: DNA extraction is one of the common experimental steps in biological research. Centrifuges can be used to separate DNA from other cell components, resulting in a pure DNA sample.

- Protein purification: Centrifuges can be used to separate proteins and other cell components. By centrifugation, protein samples with higher purity can be obtained for subsequent studies.

- Organelle research: Centrifuges can be used to separate and study organelles, such as mitochondria, lysosomes, etc. By centrifugal separation, a pure organelle sample can be obtained, and its structure and function can be studied in depth.

Third, the development trend and prospect of centrifuges

With the continuous progress of science and technology, centrifuges are also constantly developing and innovating. The following are several development trends and prospects for centrifuges. - Automation and intelligence: Future centrifuges will tend to be automated and intelligent. By introducing automatic control and intelligent algorithms, centrifuges can achieve more precise and efficient sample separation with less interference from human operation.

- Versatility: Future centrifuges will have more functions. In addition to traditional centrifugal separation, centrifuges may integrate more experimental functions, such as temperature control, fluorescence detection, etc., to meet the needs of more sample handling.

- Miniaturization and portability: Future centrifuges may tend to be miniaturized and portable. By reducing the size and weight of the centrifuge, it is more portable and convenient for use in scenarios outside the laboratory, such as field research, medical diagnosis, etc.

In SUMMARY:

As an important experimental instrument, centrifuge plays an important role in the fields of biology, chemistry and medicine. Through the role of centrifugal force, the centrifuge can separate the different components of the sample, so as to achieve the analysis and research of the sample. Centrifuge development trends include automation and intelligence, versatility, and miniaturization and portability. In the future, centrifuges will continue to play an important role in scientific research and laboratory work, providing scientists with more accurate and efficient experimental tools.