Description

Product Description

Centrifugal separators are driven by the technique of centrifugation. Centrifugation utilizes centrifugal force to separate particles from the solution. This process is mainly employed to separate two immiscible substances existing in a solution.

The efficiency of centrifugal separation will depend on the difference between the specific gravity of the liquid and the solid being filtered. This separation efficiency will increase if the difference is large. The separation efficiency is also affected by the particle size. For most separators, 40 microns is considered the visibility threshold

Centrifugal separators are used in a variety of industrial applications, owing to various advantages they offer. They have a few moving parts than other separators and have no filters, bags, screens, as well as cartridges, which makes them an ideal choice for various industrial applications. In addition to their design advantages, these separators provide the following benefits:

Maintenance Free: The centrifugal separator is largely maintenance-free owing to the absence of moving parts or other components. It is designed to flush the debris and contaminants automatically.

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

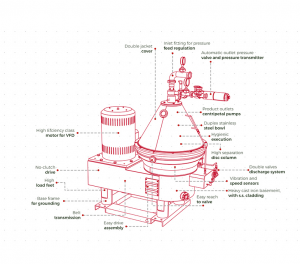

Structure

Application

Dairy separator: used for milk skimming or milk clarification (removal of solid impurities). The small separator is driven by hand and is used for manual slagging, which is suitable for farmers and herdsmen in pastoral areas; the large separator is used for industrial production and is driven by electricity. The slagging method is manual slagging or ring valve slagging.

Mineral oil separator: It is used to remove water and mechanical impurities from mineral oil such as fuel oil, diesel oil, lubricating oil and transformer oil, and can also separate similar emulsions.

Vegetable oil separator: used for the processing and refining of vegetable oil.

Animal oil separator: used for refining animal fats in meat processing, or used for concentration and separation of fish oil in aquatic processing.

Yeast separator: used to concentrate yeast and discharge slag from nozzles.

Starch Separator: Used for removing protein from starch and concentrating starch, and discharging slag from nozzle.

Lanolin Separator: It is used in wool spinning industry to extract wool grease from wool washing water and discharge slag from nozzles.

Pharmaceutical disc separator: used in the extraction of antibiotics, vitamins, etc. in the pharmaceutical industry, and also suitable for the separation of liquid-liquid-solid three-phase mixtures in pharmaceutical and chemical production.

Beer separator: used for clarification of beer, wort and other beverages.

Latex separator: used to concentrate and remove impurities in rubber latex.

Paint separator: used to separate impurities in paint and improve the quality of paint.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.